Overview:

Apply to stock, such as locomotives, EMU, LRV etc.

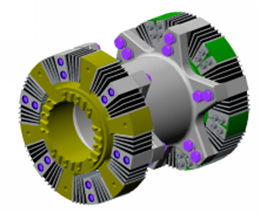

Structure and the function:

1. Hollow tube:the intermediate pipe is used to connect the gearbox side with the wheel (or axle) and achieve torque transmission.

2. Rubber:Realize displacement compensation and isotropic stiffness performance requirements for couplings.

3. Gear flange:Gear connection can transmit torque more effectively and smoothly, meeting the requirements of high torque transmission strength.

Main characteristic:

·The coupling can withstand torsional torque:44.68kNm and meet the ultimate speed :1263rpm.

·The coupling meets the requirements of axial displacement :±32mm ; radial displacement :±24mm

·Couplings can adapt to harsh environments such as high and low temperatures, sandstorms, and icing. It can also withstand the vibrations and impacts generated during train start-up, braking, and operation.

·The coupling meets the requirement of a 30-year service life, and the rubber parts have a maintenance cycle of 6-8 years.

Capabilities:

·Having a mature product structure design system, a professional rubber formula research and development team, and strong FEA simulation calculation capabilities;

·Meet the flame retardant requirements of EN45545 and the safety index requirements of rail trains.

·Having national certification qualifications and being recognized by the DNV · GL laboratory of the classification society, it is a designated freight product filing laboratory by China Railway Inspection and Certification Center (CRCC).

Types:

More Details: