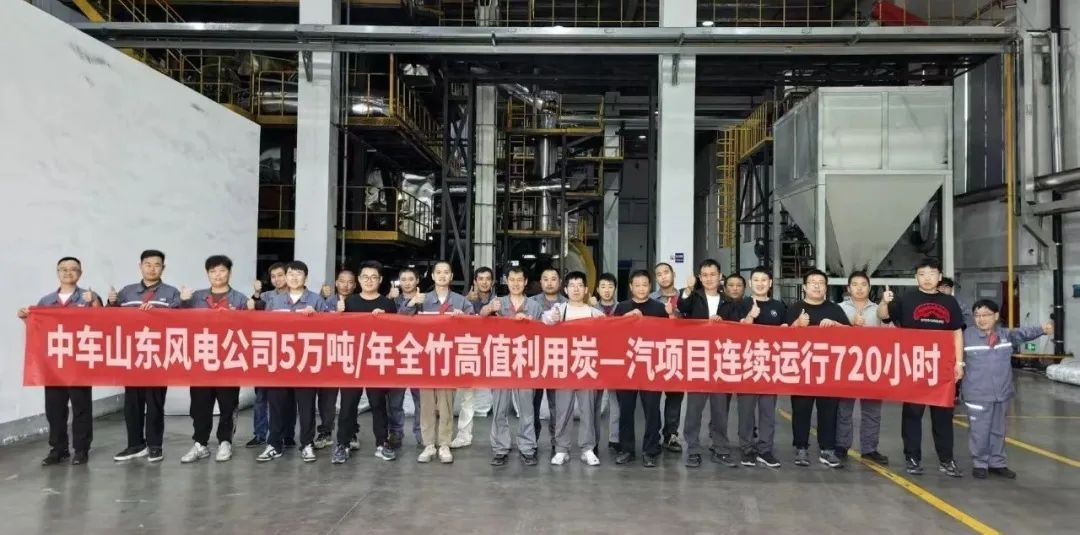

Recently, CRRC's “Charcoal–Steam Cogeneration Project for High Value Utilization of Bamboo” has achieved continuous and stable operation in Chizhou, Anhui.

To efficiently and cleanly handle the large amount of bamboo scrap generated during bamboo product manufacturing, CRRC Shandong Wind Power conducted thorough research and decided to build upon the pyrolysis technology to convert this waste into charcoal and steam, enabling the clean and efficient utilization of the entire bamboo plant.

The biomass charcoal powder produced through pyrolysis can be used as high-end activated carbon or premium raw material for sodium-ion battery anodes. Meanwhile, the high moisture content in fresh bamboo scrap is converted into steam during pyrolysis. The steam can be directly used in the drying process of bamboo products, effectively replacing traditional fossil fuels such as natural gas, achieving a closed-loop energy cycle and reducing carbon emissions. This project marks a major breakthrough in the stability, reliability, and process maturity of the project equipment, laying a solid foundation for large-scale implementation and replication.

Looking ahead, CRRC will continue to actively implement China’s “Dual Carbon” strategy, drive product innovations, expand its portfolio of green solutions across diverse application scenarios, and contribute to a more sustainable development.