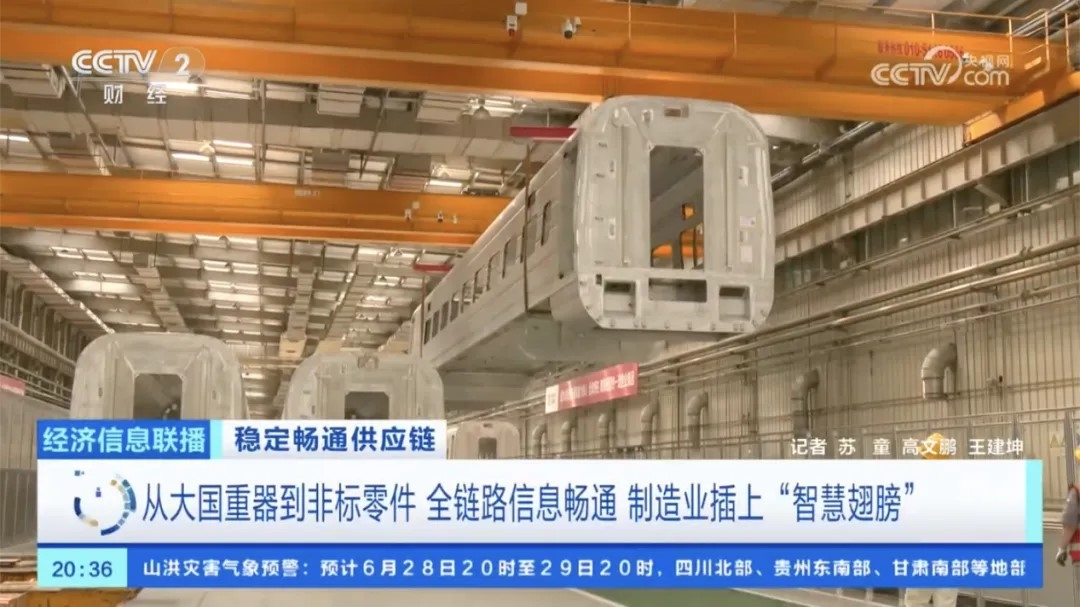

As China’s manufacturing sector accelerates toward intelligent transformation, CCTV Finance’s Economic Information Broadcast recently spotlighted CRRC’s digital production capabilities under the theme “Stable Supply Chains, Smart Manufacturing.” The report featured the fully digitalized production line at CRRC Tangshan, where a Fuxing high-speed train car body can now be assembled in less than half a day.

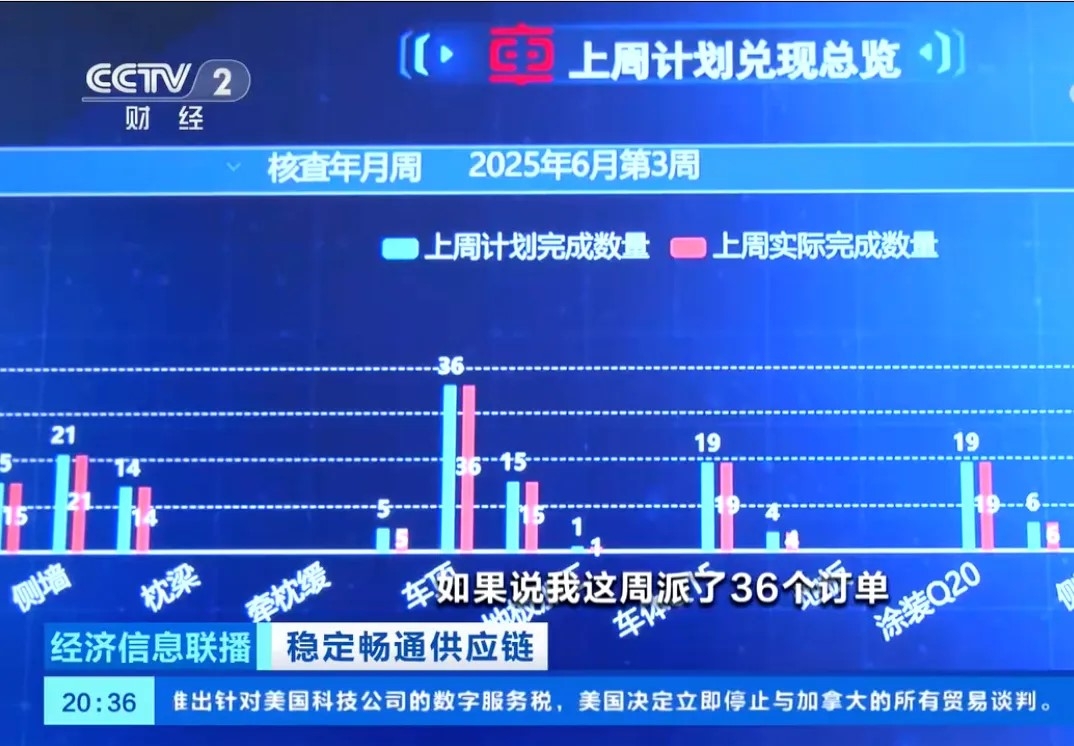

The plant’s core components and logistics are handled entirely through automated systems, enabling high efficiency with minimal human intervention. Robotic arms, welding robots, and automated guided vehicles collaborate to assemble aluminum alloy structures, while integrated dashboards display real-time progress across 36 major components—supporting data-driven scheduling and production decisions.

Currently, CRRC Tangshan is producing both 350 km/h Fuxing EMUs and 140 km/h intercity EMUs on the same line. The system automatically splits order data and assigns tasks across the production chain, enabling flexible, multi-model manufacturing. Custom-designed tooling allows fast switching between projects, making it possible to run up to three metro lines in parallel.

Digitalization has also brought significant efficiency gains: labor input in the car body workshop has dropped by two-thirds, while productivity has risen to a pace of three car bodies per day.

Beyond the factory, CRRC’s life-cycle digital platform tracks real-time operating data from delivered trains—such as those in service in Taizhou, Zhejiang. Remote monitoring and AI-powered image analysis reduce maintenance staffing by 20–30%, while supporting cost control, operational stability, and future design improvements.