CDJF208A1 Main Generator

Source:

DateTime:2017-09-19

CDJF208A1 Main Generator

|

Product Name

|

CDJF208A1 Main Generator

|

|

Volume (length*width*height:cm)

|

1351.5*1690*1682

|

|

Weight(kg)

|

6708

|

|

Rated output power

|

3700kVA

|

|

Rated working voltage

|

507/770V

|

|

Rated Current

|

4215/2775A

|

|

Rated rotating speed

|

1000r/min

|

|

Maximum rotating speed

|

|

|

Rated torque

|

|

|

Starting torque is no less than

|

|

|

Motor insulation grade

|

H

|

|

CDJF208A1 main generator is developed by removing slip ring and brush system and increasing AC exciter and rotating rectifier assembly based on JF204D and JF204DZ traction motor. Without the electricity conducting process caused by sliding contact in the whole mechanical and electric energy conversion process by removing slip ring and brush, it succeeds in avoiding reduced or even inefficient insulation for the motor caused by carbon powder so as to reduce maintenance and enhance the reliability of main generator. In the meantime owing to the fact that there’s no need of inductor exciter and excited rectifier cabinet and excitation line with large current in the locomotive by installing exciter and rotating rectifier module within the main generator, it enables the locomotive configuration simpler and more convenient. JF208A1 is exported to such country as Iran and Saudi Arabia.

|

|

Technical Feature

1. Motor structure: being three-phase brushless excited salient pole synchronous generator with horizontal single bearing structure, E32626QTY single-row cylindrical roller bearing is installed at shaft extension end with shat extension 1:10 taper to help transmission and the other end is connected to diesel engine by flexible coupling.

2. It adopts protection axial self-ventilation with cooling air entering from end cover air inlet and discharged from air outlet in the frame.

3. Excitation: brushless excitation

|

|

Technical Advantage

1. Without the electricity conducting process caused by sliding contact in the whole mechanical and electric energy conversion process by removing slip ring and brush, it succeeds in avoiding reduced or even inefficient insulation for the motor caused by carbon powder so as to reduce maintenance and enhance the reliability of main generator.

2. Owing to the fact that there’s no need of inductor exciter and excited rectifier cabinet and excitation line with large current in the locomotive by installing exciter and rotating rectifier module within the main generator, it enables the locomotive configuration simpler and more convenient.

|

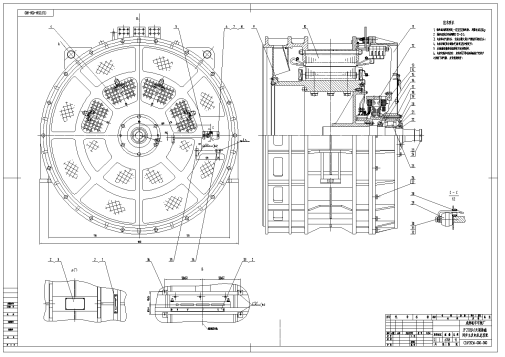

CAD Drawing