Recently, the preferred shortlist of 2018 major scientific and technological innovation achievement (technical project, patent, technical standard) of railway was released. Among the 49 selected railway technical standards, 2 national standards and 2 railway industry standards led by CRRC SRI are included.

What are the national and railway industrial standards made by CRRC SRI?

DC 600V power supply system of passenger train

Standard number:GB/T 32587-2016

DC600V power supply voltage system is the innovative and unique voltage system in China to supply power from locomotive to passenger train after the axle-driven DC48V, diesel engine set power generation, AC380V power supply voltage system of passenger train. It involves railway passenger car, electric locomotive, diesel locomotive, power generation car and ground power supply system etc.

This standard specifies the technical requirements, test methods and inspection rules of DC600V power supply system and components on passenger train. The standard puts forward the DC600V passenger train power supply system, various technology and performance indicators, leading the international and foreign standards. It reflects the advanced technology level of China railway in the field of train power supply voltage system in the world and has great significance of guiding the train power supply development.

Electrical control cabinet of railway passenger cars and EMU

Standard number: GB/T 32595-2016

The electrical control cabinet is an intelligent integrated control cabinet integrating the power supply switching control, air conditioning unit control, battery under voltage protection, lighting control and other functional units. It is the main control unit for railway vehicle inspection, control, diagnosis protection, information prompt and network communication. With the rapid development of China’s railway, the design, manufacturing and inspection of electrical control cabinets for passenger cars and EMUs are lack of uniform standard, which stands out day by day and directly affects the operation safety and reliability of railway passenger cars and EMUs.

This standard has completed a large number of fundamental research and article compilation, and experts from relevant domestic fields are invited for feasibility study and review to ensure the normalization and authority of the standard. The technical terms refer to current technical requirements of electrical control cabinet for railway passenger cars, or originate from the advanced standards at home and abroad which have been verified for many years, and have wide applicability and advancement.

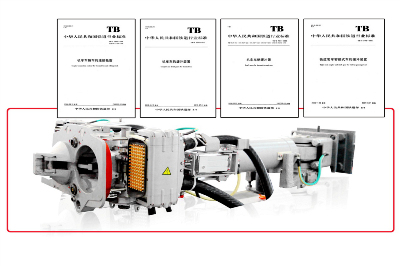

EMU car body structure strength design and test

Standard no.: TB/T 3451—2016

Due to the difference between the structure characteristics and operational mode of EMU and those of the domestic main line passenger cars, TB/T 1335-1996 "Code for Strength Design and Test Appraisal of Railway Vehicle" is not suitable for the EMU car body structure, and we lack the implementation standard in terms of the EMU car body strength design and test.

Since the formal implementation of this standard, various EMU design and manufacturing OEMs have used this standard for a large number of EMU car body structure and test. With good practicability, this standard is applicable for all types of EMUs operated in China, laying a solid foundation for the technical development of China EMUs.

Centralized axle-temperature alarm of railway passenger cars

Standard no.: TB/T 2226-2016

With the speed boost of railway passenger cars, the axle temperature becomes higher and higher, so the axle-temperature detection plays a more and more important role in operation safety. The requirements for axle-temperature alarm of railway passenger cars are increasing, but the original TB/T 2226-2002 "Technical Conditions for Axle Temperature Inspection and Alarm for Railway Passenger Cars" has insufficient circuit protection and flame retardant requirements for centralized axle temperature alarm, so the potential safety hazard exists.

This standard specifies the system composition, type dimension and identification, technical requirement, inspection method, inspection rule and marking, package, transport and storage of centralized axle-temperature alarm for railway passenger cars. Applicable to the current centralized axle-temperature alarm for current railway passenger car, this standard defines the product requirements, and can effectively prevent the operational accidents after implementation and plays a significant role in vehicle operation safety.

Recalling the eventful years, as the “pathfinder” and “pacesetter” in the innovation field of CRRC, CRRC SRI has always been committed to strengthen the technical R&D innovation, constantly enhanced the communication and cooperation with relevant units and taken the lead in technical R&D development and industrial standard formulation.

Looking forward to the prosperous future, CRRC SRI will adhere to lay emphasis on both technical R&D and industrialization development, constantly devote greater effort to innovation, rapidly realize the transformation from technology to industrialization, help China high-speed railway “go out” with first-class technical achievements, assist the high-end equipment manufacturing development with first-class performance, and strive to build the respectable, valuable and intelligent company.