By Zhang Lipeng in Beijing | CRRC | Updated: 12/03/2018

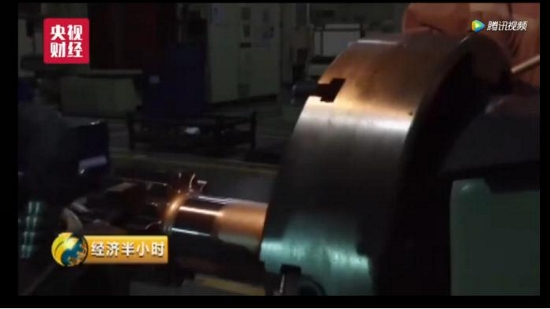

The high-speed rail industry started late in China compared with some developed countries, and all the high-speed rails followed the German or Japanese standards. However, the “Renaissance” EMU train independently developed by China has extensively adopted technology standards of China, such as Chinese National Standards and company standards of China Railway Corporation. Among the 254 important standards of the train, Chinese standards account for 84%, making it the real “Made in China” EMU train. In Changzhou City of Jiangsu Province, there has emerged lots of factories that provide supporting facilities for the“Renaissance” EMU train. The gear case is the core part that makes it possible for the“Renaissance” EMU train to drive with high speed. Its service life can reach 24 million kilometers for 30 years, which equals to 600 circles around the earth, and the surface accuracy of its components is one fiftieth of a hair. Nowadays, multiple technologies of the“Renaissance” EMU train have been leading in the world and the “standards” created by engineers in China have gradually become the new target of the world.

The extremely high on-time rate and faster arrival speed show the dynamic performance of “Renaissance” EMU train. According to the experimental data, the“Renaissance” EMU train is much better than the “Harmony” bullet train in terms of acceleration performance, fastest speed, the rigidity and stability of the train and the noise decibel. This is attributable to the huge upgrading of the manufacturing standards of China’s high-speed rail.

During high-speed driving, the body of“Renaissance” EMU train need to stand extremely high pressure and air friction, and a tiny flaw of the weld joint may split the train body. However, the designed life cycle of“Renaissance” EMU train reaches a length of 30 years, 10 years longer than the last generation. This is because a top-secret new welding technology has been applied. The welding technology that leaves no trace is called “friction stir welding” inside the industry and is the most advanced welding method in the world. It is mostly used in the sophisticated aerospace manufacturing field and this is the first time that it is applied in the manufacturing of trains, which sets another “world record”.

Nowadays, the“Renaissance” EMU train has realized successful docking with other high-speed rail trains, which means all the trains in China’s high-speed rail network will be included in an unified standard, under which different high-speed rail trains can be marshalled together to cross different regions and experience different weather in China and show the maximum efficiency of high-speed rail network.

The core part like the gear case is produced in a factory in Changzhou City.

The workers call this special workshop an “intelligent assembly line”, which includes the general assembly process of the gear case. At this vital step, the assembly of components is exceedingly demanding regarding the temperature and humidity. Even the rise of humidity resulting from a rain can affect the reliability of the components.

The reason why the workshop is called an “intelligent assembly line” is that all the steps have data control and the workers’ intelligent spanners can give twisting force according to the computer settings so as to realize the first-class precision of each bolt’s degree of tightness. The workers are reminded to carry out the operation when the green light is on. If a step is inconsistent with the command, the system will record it and raise the alarm in time.

What foreign experts have not thought of is that China has mastered this technology in just 10 years, and it has been extensively used on the "Renaissance" EMU trains. At present, it has occupied 80% of the domestic market. The last "foreign trace" in China's high-speed rail will be replaced.

China’s high-speed rail network crosses from Guangzhou in the south to Harbin in the north and traverses from Shanghai in the east to Urumchi in the west, with the longest route reaching 2,000 kilometers. The most advanced high-speed rail technologies abroad are unsuitable because of the effect of altitude and temperature difference, and the foreign manufacturing standards fall behind the development of Chinese high-speed rail.

China’s huge high-speed rail network brings both challenges and opportunities. In 2015, the“Renaissance” EMU train with domestic gear case came out. While it passes all the tests, it also provides a new standard, “Chinese standard”, for the manufacturing of world’s high-speed rail trains.

If you want to know more information about this, please contact zhanglipeng@crrcgc.cc